SENFA offers innovative solutions based on cutting-edge French expertise of technical coating up to 5.1 metres. The coating process involves the application of a paste to the surface of the textile, combining substrates to create added functionality and value. Some examples of the coatings offered include blackout, opacifier, fire-retardant, light diffusion, matt effect, glitter effect, double-sided and acoustic.

These features can be combined to create various end products, including unique advertising panels, specialised curtains for hotels, or wall decorations with acoustic properties. Predicting upcoming trends on both national and international markets allows the business to develop new and technically innovate textiles, with each one being better than the last.

OVERVIEW SENFA SERVICES

OUR EXPERTISE

Driven by pioneering spirit and innovative capability, SENFA has invested in new technologies over the years to develop their know how, expand their product range and offer specific commission coating to their customers. Utilising specialised equipment, they offer a wide range of industrial processes and services as set out below :

CUSTOM-MADE FORMULATION

SENFA’s team of engineers and scientists are on hand to develop formulations,

and offer a custom-made service to create a specific chemical formulation upon request.

QUALITY CONTROL

MATERIAL TESTING

& CHARACTERISATION

SENFA work to high standards, ensuring that their substrates are subject to strict quality assurance standards and lab testing as required by specific markets. This includes international regulations, fire-retardant standards, and other performance requirements.

The section below gives an overview of the tools we utilise to assess the quality of fabrics throughout the production process:

FIRE RETARDANT M1 TEST

& COMPLEMENTARY TEST

M1 - NF P 92-507

DYNAMOMETER

TEST

Tensile Strength EN ISO 2411

Rupture resistance EN ISO1421

Tear resistance EN ISO 1875-3

BREATHABILITY

MASK TEST

Filtration efficiency EN 149

SPRAY TEST

Water Repellency - EN ISO 4920

WATER

COLUMN

Water resistance test

KUNDT'S TUBE MEASUREMENTS

ACOUSTIC TEST

BREATHABILITY

SUBSTRATES

SPECTROCOLORIMETER

MEASUREMENTS

Software Spectra Magic NX

D65 10° spectaculaire ΔE CMC

SUN

TEST

Artificially accelerated ageing simulation of products subject to light

SURFACE

TENSION & ENERGY

FINISHING PROCESSES

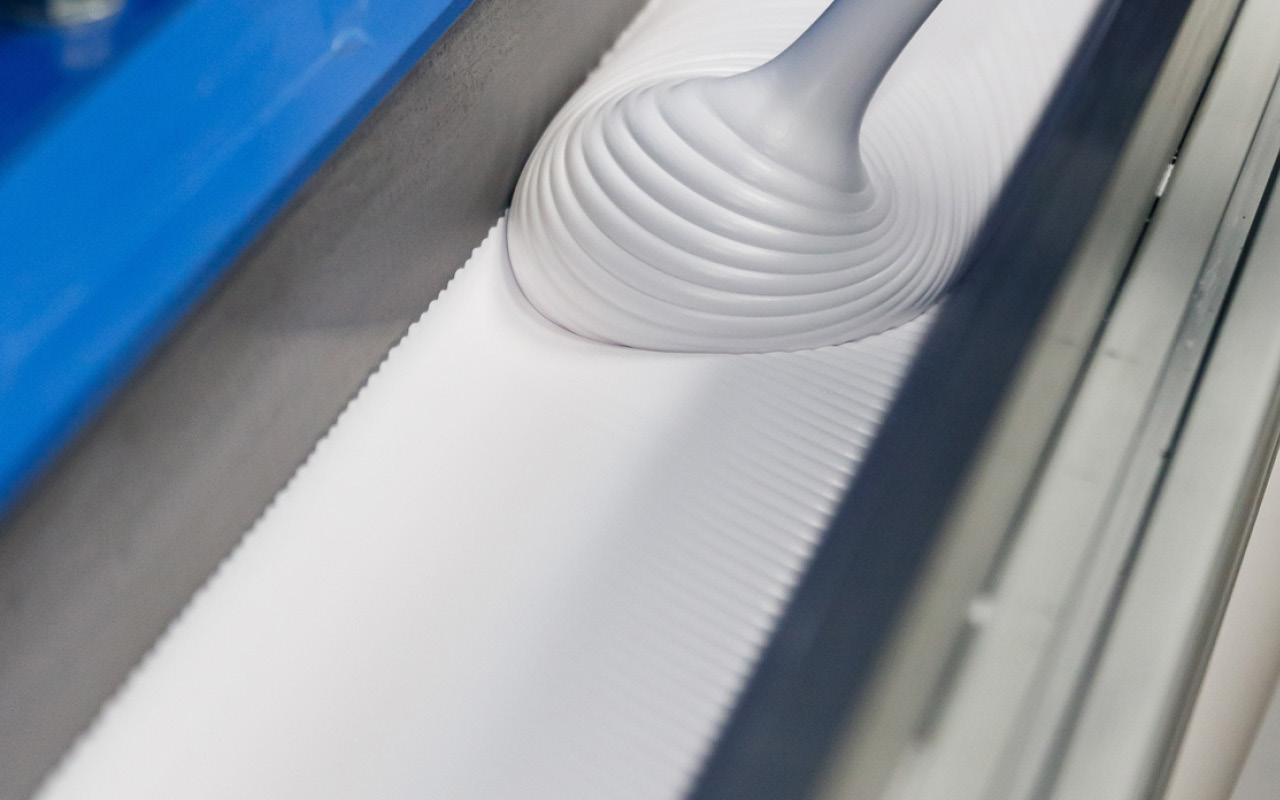

COATING

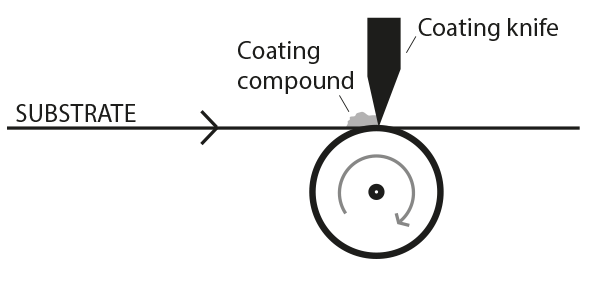

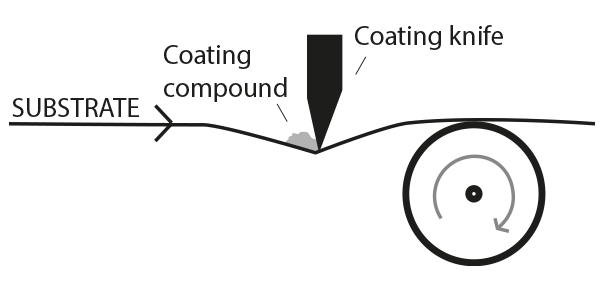

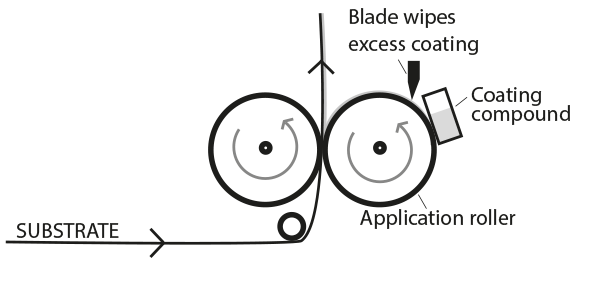

A coating is a covering that is applied to the surface of a substrate. This finishing process can be both decorative (colour, mat, glitter…) or functional (fire-retardant, blackout, acoustic, waterproof…).

DYEING

The dyeing process involves the application of a coloured dye to a particular material, such as yarns, other fibres or fabrics.

LAMINATING

Lamination is the process of applying a substrate in multiple layers to provide a particular property, including added strength, stability, or an alternative appearance.

PADDING

This process involves the impregnation of a chemical primer to the substrate by immersing it in a bath before passing it through a set of rollers.

FLOCKING

This process applies small fibre particles to the surface of the substrate which can offer a soft touch to the fabric or improve the appearance.

COATING TECHNOLOGIES

Our technologies allow us to meet your specific requirements thanks to paste and foam coatings (PVC FREE). Those finishing processes can be associate with various coating methods such as :